We hope you had a great relaxing summer and as it comes to a close, we look forward to getting back to work with you.

We hope you had a great relaxing summer and as it comes to a close, we look forward to getting back to work with you.

I’ve been meaning to write about Solares Architecture Inc. for some time now. Sure you can judge this book by the cover and be delightfully pleased, but as you tuck in past the cover, the real seduction begins!

Like most architects Christine Lolley and Tomislav Knezic are passionate about what they do. Where their practice diverges from other architecture firms is in the fact they go beyond simply creating a welcoming space to call home. They go beyond by brazenly having everything they’ve ever worked on performance tested for efficiency.That’s right, they have everything physically tested and indexed on the well-known EnerGuide for Houses standard energy rating system. Most firms are content to rest on their aesthetic laurels, but Solares goes few steps further; they have their homes – new and old – tested, inspected and reported on. I’m unaware of any architecture firm in Canada that’s subjected themselves to this level of performance scrutiny.

We like to think we’re Solares’ eyes and ears in the field. They set the performance specifications for the builder and we work with the builder in ensuring the envelope assemblies get put together as specified. We report back to Solares with information they need to ensure the build is on track to perform as planned. Once a year, we meet up with their entire staff and review the year’s projects to find strengths, weaknesses and opportunities for their energy performance to grow in future projects.

As Solares’ portfolio of projects increases as does their commitment to refining energy efficient design, we at BlueGreen Group will march down that path with them every step of the way!

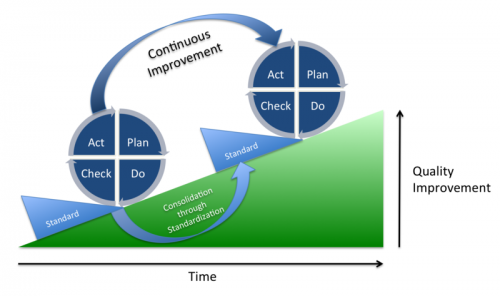

BlueGreen Group takes care of the “Check” part of the cycle, and if the builder or renovator is off track on the set performance standard, it feeds the “Act” part of the cycle where the architect can work with the builder to ensure performance is built in. We’re invited back yearly to review projects with the Solares staff to inform changes in the way they “Plan” and “Do”. Source: http://en.wikipedia.org/wiki/File:PDCA_Process.png

We dropped in on Manny and Anderson of Hardcore Renos to see how their first new build was progressing; very well thank you!

Shervin laying all on the table helping to weigh the various energy upgrade options for the build. These guys are serious builders who want the best for their client and have invested in a planning process and have set targets for testing the home’s performance. In the end the homeowner wins.

We’ve known for years that heat escapes in all directions but its been difficult to convince builders and home owners to invest in sub-slab insulation. Of course, with the rise in popularity of radiant in-floor heating for the basement, insulating the slab is minimum code. We say it’s just common sense.

On this job site though, we saw something different, kinda like Nigel’s amp going to 11 in Spinal Tap. This house had sub-slab insulation WITH a THERMAL BREAK at the edge! I should have figured it was sprayed by Rich Krechowicz of CallRich Eco Services Inc his crew executed the job flawlessly.

Photo 1: The beige colour above the basement slab is spray foam. If you look closely, you will notice the foam tapers from 2.5″ thick on the wall and feathered up to nothing.

Photo 2: A close-up detail of the Photo 1 shows the foam thickness between poured concrete wall and slab.

I spoke to Mr. Krechowicz recently and he agrees “The concept of using spray foam is relatively unknown, so we don’t have these jobs too often. The thermal break is so important and it is a detail that is mostly ignored or overlooked by contractors.” and I completely agree.

The drawing shows the continuous insulation under the slab and around edge to insulated wall. Source: Building Science Info-513: Slab Edge Insulation. Click above for link.

The loss at slab edge is significant and is more obvious in wintertime when snow accumulates along the foundation wall. Mr. Krechowicz says “At my house I have a non-thermal break in the part of the house that is slab on grade, and you can see the melting of snow along the perimeter.” The cobbler’s shoes…

Krechowicz goes on to say “Another benefit to using spray foam is that it makes the job of securing radiant floor tubing a breeze, as the staples can be attached directly to the foam.”

For a great article on the topic, check out the Journal of Light Construction’s Insulating a Slab With Spray Foam by Mike Pindle, Jan 2010.

In an earlier post, I blogged about the potential for spray foam to go off ratio which brings me to the last point about spray foam. The person pulling the trigger needs experience and has to have a solid understanding of building science in order to do their job properly.

As we blogged about in an earlier post on achieving great success with Insulated Concrete Form (ICF) homes, we know that when detailed by an expert contractor, ICF homes can be VERY air tight. A tight home is a highly desirable feature if heat recovery ventilation systems are installed. There’s lot to like about method of construction, but it should be noted there are a few significant drawbacks.

First and foremost, there is nothing sustainable about using tons of concrete and foam. As Paul Hawken would say there’s a lot of Heat, Beat and Treat that goes into producing and shipping these materials. Both are an order of magnitude more energy intensive to make than say recycled cellulose insulation per m3 material.

Ted Kesik’s nightmare: The best intentions in using highly efficient ICF will be negated on this project due to the continuous concrete floor slabs running from inside to outside the unit. Luckily, you will see the HVAC duct work installed up front to valiantly ease the condensation and curtain of cold air that will stream from these lovely south facing windows come winter time.

Another issue with ICF – and with Stucco application for that matter – is the waste created and widely deistributed. The forms used in ICF are usually made of expanded polystyrene, the same material used as a substrate in stucco application. Again, both these products perform very well, but its not uncommon to see small clouds of tiny foam beads pushed off a construction site and into the neighbourhood and down municipal drains.

Can we build better and pollute less both in the production and construction side of the equation: YES!

For Immediate release: July 3, 2013

By Greg Labbé

Toronto, ON – Many Toronto homes built between the wars have uninsulated walls. As home owners look to make their homes more comfortable and cheaper to operate, they may be unwittingly causing long-term damage to their vintage homes by insulating them without air sealing them.

The large number of solid double brick homes still in use today is a testament to their durability. By virtue of being uninsulated, the walls and structure of these homes were continuously dried by the warm conditioned space radiating and leaking massive amounts of warmth outwards drying the building. The heat leaking out kept mould out of the wood structure and the bricks from degrading. However, when the home’s envelope is improperly insulated or air sealed, it can lead to unwanted deterioration.

Greg Labbé, co-owner of BlueGreen Consulting Group Inc. (BGG) has seen many examples of homes insulated with good intention, but having disastrous effects on the building shell. “Few homeowners understand that though insulation is sorely needed to bring these buildings up to modern performance levels, air sealing trumps insulation” Labbé says. Over the past 14 years he’s been in countless attics where the roof sheathing is falling apart because the warm conditioned air leaks make it past the needed insulation but is stopped by the cold attic as the vapour turns to liquid causing mould and premature rotting of the wood structure. “Our limited testing has shown that as much as 25% of a semi detached home’s air leakage can come from the party wall. With this study, we aim to get a better understanding of the significance and potential impact this air leakage may have on heat loss and unwanted moisture getting trapped in the attic.”

The semi-detached double brick home is the most prevalent in Toronto and Labbé feels there’s an urgent need to start studying all aspects involved in the techniques to properly retrofitting these homes as more and more homes get Deep Energy Retrofits (DER).

The project is being funded by a grant from the Natural Sciences and Engineering Research Council Applied Research and Development program allowing BGG to hire students from Humber College’s Sustainable Energy and Building Technology program to complete the study. The students along with community volunteers at Project Neutral will test homes in the Junction and Riverdale neighbourhoods of Toronto this summer.

BGG will work with professor Russell Richman from the Department of Architectural Science and Graduate Program in Building Science at Ryerson University to characterise the level of air leakage specifically in semi-detached homes and they hope to find predictive ways to estimate air leakage through the porous party wall by testing a number of semidetached units simultaneously. “Heat loss in the form of air leakage to the party wall can be a significant energy penalty and needs to be controlled in these homes.” and Mr. Labbé hopes that by quantifying the level of air leakage, his group can draw attention to the issue which many contractors are unaware of when they renovate homes. Labbé adds “If you live in a semi-detached or row house and would like to volunteer you and your neighbour’s house give us a call!” saying the test takes less than an hour and is free of charge.

For more information please check out our web site www.bluegreengroup.ca or to schedule an interview, please contact Greg Labbé at 416.799.0408 from 9AM-5PM Monday to Friday. To take part in the study www.bluegreengroup.ca/doublebrick

“I refuse to condemn your generation and future generations to a planet that’s beyond fixing,” President Obama said to a gathering of students. In clear support of scientists he gave a blow to skeptics of climate change in saying “We don’t have time for a meeting of the flat earth society.”

Is this the first of a political sea-change? Though the talk was short on action and specifics, its clear President Obama will continue to accept the bounty of fracking as a transition fuel and the plan calls for more nuclear.

“President Obama just laid out his plan to address climate change, and as we were hoping he gave the Climate Declaration a shout out. The Declaration helped to give the President the critical support he needed from the business community” reports CERES.

We’ve been in the business of making recommendations on how to insulate double brick (aka solid masonry) walls for over 14 years now and there have always been fears, risks and dangers associated with insulating these load bearing walls. Frankly, the concerns are enough to keep a building scientist up at night.

Our interest in double brick homes comes form the fact that we both live in 100 year old homes in Toronto and we always tried to keep up with the bits and pieces being published in Europe and North America.

In a recent blog I mentioned Building Science Corps awesome technical report on Internal Insulation of Masonry Walls as well as Measure Guideline: Internal Insulation of Masonry Walls and now I see they’ve gone one step further and produced another great study on the subject Interior Insulation of Mass Masonry Walls: Joist Monitoring, Material Test Optimization, Salt Effects Research Report – 1307 May 2013 Kohta Ueno, Randy Van Straaten and Chris Schumacher.

A big thank you to the United States government who’s Department of Energy branch funds this prescient scientific research.

So if you or your loved one lives in a leaky, uninsulated double brick house, give the paper a read over! If you’re a contractor, insulator, architect you have to read this before you do another project!

Derek Satnik of Mindscape Innovations Group Inc in Waterloo, has written a great article on the present state of Ontario’s Electricity woes in his blog World Bank & CIDA Oppose Canadian Nuclear.

The article says “Ontario has tremendous opportunity right now. As its aging nuclear fleet comes due for replacement, Ontario is ready to simply turn them off one at a time, and replace them with a combination of conservation, combined heat and power, hydro power imports from Quebec, and local renewable generation (wind and solar). This could be done at great savings to the public, and would put Ontario among a growing list of jurisdictions that is transitioning to a more distributed, collaborative, transparent, and sustainable energy system. And this could be done while pioneering a new nuclear industry revolution, and being the world leaders in decommissioning. Somebody will lead that charge: will Ontario have the vision for it?“

We had a chance to go over the energy modeling results yesterday morning with Anderson Hinds and Manny Neves of Hardcore Renos at their job site; it was authentic!

When they finally climbed out of the rain-drenched trenches, we got down to work, talking about various upgrade scenarios that will see their client cut energy consumption by nearly a quarter. They realise that building to code minimum is not where they wan to take their business. These guys get it with their focus on the client.

They want to build durable homes that are attractive, functional, comfortable and an investment that saves the home owner money. They’re investing upfront on science-based advice that makes the tough choices on various upgrades clear as a bell.

Shervin takes Anderson and Manny through some upgrade scenarios that will see the efficiency of this package J house increase by 22% with a few simple changes to the building shell.

The tough technical questions were punctuated by punchy humour and this team of bon vivants clearly loved what they were doing.

For high performance home designers and builders, there are compelling reasons to install windows more towards the outside to get more solar gain and reduce water management elements on the outsie. We call these windows “outties.” However, there is a balance between optimal solar gain, reduced thermal bridging and minimised exterior elements to manage rain water.

Placing the window more in the middle of the insulation assembly reduces the thermal bridging but exterior rain water management gets more complicated too. Placement is a fine balance and requires planing and good execution on the part of the installer.

This door was framed into the poured concrete wall as an “Outtie.” Clearly, the door is not tied into the air barrier system nor is it tied into the insulation. Typically, jamb extensions will be placed over this significant thermal bridge and the joints will leak air if not caulked. Had the door been installed as an “Innie”, the energy performance would have increased, though it would have required more effort on the outside in terms of flashing and rain water management.

What we all agree on though is that both windows and doors have to form part of the insulative layer and be tied into the air barrier system. The returns are typically not insulated and if they bridge a gap between the window and the insulation, you can kiss all the best intentions of a good high efficiency window goodbye.

This window was installed into the poured concrete wall as an “Outtie.” Clearly, the window isn’t tied into the air barrier system nor is it tied into the insulation. This is a significant thermal bridge and the joints will leak air if not caulked. Had the window been installed as an “Innie”, the energy performance would have increased, though it would have required more effort on the outside in terms of flashing and rain water management.

As we tour and test houses, it’s clear to us that old habits die hard and many builders and trades people just aren’t aware of the facts about window and door placement, especially when they are mounted in foundation walls or on slabs.

The above shows where an insulated slab on grade meets an exterior door. If you look closely from the door threshold in, you’ll see 1″ of exterior uninsulated concrete foundation wall-top, 2.5″ of expanded polystyrene and finally, the inside warm concrete slab. Had the doors been installed a mere 5″ in, the door frame would have straddled both the foundation wall and the slab making a solid thermal connection with the slab edge insulation.

On your next project, pull your window and flashing installers together and get them talking so they avoid making these mistakes. It might also be beneficial to redesign the window bucks for foundation pours to allow for better drainage should an “innie” be selected.