If you missed last weeks High Performance Meets Boots on the Ground Event held at our office, we can’t give you the networking part, but here’s the complete technical part. Enjoy!

If you missed last weeks High Performance Meets Boots on the Ground Event held at our office, we can’t give you the networking part, but here’s the complete technical part. Enjoy!

Passive Buildings Canada recently posted a presentation we gave at their fall 2015 AGM. The talk covered the latest findings based on our testing and field observations.

Here it is in all it’s unexpurgated glory!

I marvel at the late English steeplejack, Fred Dibnah, who’s work was highlighted a number of years back by the BBC’s Made in Britain. I’ve always loved to listen to Fred ramble on as he goes about his work at high altitudes with little to no protection.

Here, he can be seen painstakingly putting up a series of maybe 20 ladders just to inspect the chimney so he can prepare a quotation for services. So the next time you complain about the effort it takes to put a quotation together, have a look at this wonderful short:

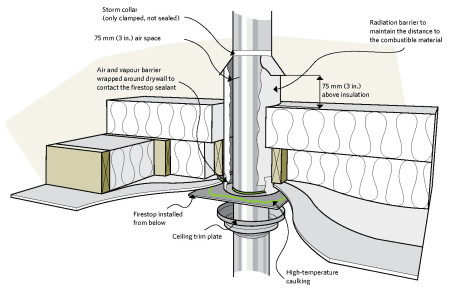

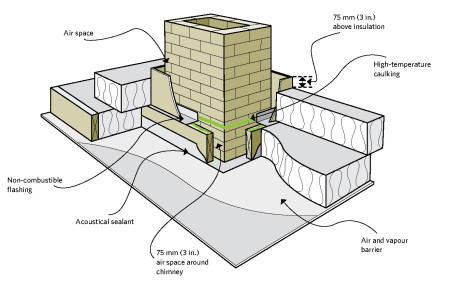

Getting a good air seal around chimneys – be it masonry or metal – is always challenging. Although the details could be more clearly defined, I was happy to stumble on Natural Resources Canada’s following detailed drawings in the latest version of Keeping The Heat In:

Though in concept good, there are two clarifications the illustrator needs to more clearly define. It would be nice to know if the ceiling flange (labeled ‘fire stop’) connects to the outside face of the chimney or the outside face of the radiation barrier. Also, the detail showing the detail showing the air and vapour barrier needs to be clarified, it just shows up.

Here too the illustrator should show a bead of acoustical sealant on the cut away for clarity. This detail relies on dimensional lumber to carry the air seal, so where cross-cut, sealant or tape needs to be applied.

This past Thursday we held our 5th, semi-annual High Performance Design meets Boots on the Ground networking event and we have to say: the event is coming together wonderful and many architects and builders look forward to the even on their calendar. Once again, we wanted to thank our audience both those who came to our office and those through PBC‘s web cast and volunteers for their time and support.

Fourth Pig’s Melinda Zytaruk gave one of the fourth talks which we hope to have posted in the coming week!

Check out the beautiful people snapd caught on camera, check their Facebook page to see if you were snapd! Thanks Britney Townsend for highlighting this important event!

For a hint of “event flavour”, below are candids our photographer Dennis Keefe took that show the bridge building going on between architects and builders; these are much needed technical discussions and the BOG delivers!

For a hint of “event flavour”, below are candids our photographer Dennis Keefe took that show the bridge building going on between architects and builders; these are much needed technical discussions and the BOG delivers!

As Building Enclosure Commissioning starts to take root in Canada, we’re doing our part to offer field air tightness testing services. Having tested 2 LEED Platinum buildings and one LEED Gold building, we expect growth in the demand for large building testing. To meet the demand, we’ve recently invested heavily in 12 blower door fans with the intention of testing quality buildings in the construction phase.

So what size of building can we test with that kind of gear you ask? The answer is; it depends primarily on how much your building leaks and secondarily on the physical size!

Using the ASHRAE 90.1 Guidelines for air leakage which categories building into Air tight, Average and Very Leaky, this is what BlueGreen Group has the equipment to do:

| ASHRAE 90.1 Building Leakage Rate |

Upper limit (CFM75/Ft2) |

Maximum Surface Area (m2) |

| Air Tight |

0.1 |

55,000 |

| Average |

0.3 |

18,000 |

| Really Leaky |

0.6 |

9,000 |

Remember, that a building’s surface area includes the exterior walls, the floor (or slab foot-print) and the ceilings – it even includes cantilevered floors! To put this into local perspective, the LEED Platinum Brick Works building in the Don Valley ravine has a surface area is less than 5000 m2 and a conditioned volume of about 18,000m3.

The video below allows you to final use your French immersion skills and shows a new 39 story office tower or IGH (Immeuble de Grande Hauteur) is being tested in Lyon, France. With a total of 10 Retrotec fans – four on the 2nd floor, and two on each of the 9th, 21st and 33nd floors, this air tight building didn’t take many fans. The building owners targeted air leakage of 1m3/(hr·m2) and the results beat the target handily with a mere 0.45m3/(hr·m2). The total building volume was 180,301m3.

The video below shows a massive Amazon distribution centre being tested in Poland. With a total volume of 1,142,000m3, this is probably the largest test completed on a building to date. A total of 24 Retrotec fans were installed.

All 3 videos on this page give insights on the preparation work that goes into testing buildings. The following does a good job to describe the process for testing.

Some good news for a change! In a recent article, the Christian Science Monitor Editorial Board writes that “Like the receding tide, the fall in oil prices has exposed which commodity-rich nations have learned how to avoid the so-called resource curse and which have not. Countries such as Norway and Bolivia have effectively sidestepped many of the pitfalls of easy resource wealth, such as corruption, reckless spending, or autocratic rule.”

The editorial goes on to say “The price fall [of oil] is forcing wealthier nations with large oil reserves, such as Canada, Australia, and the United States, to focus more on sustainable industries for growth.” Let’s keep our fingers crossed!

We’ve talked about pot lights in past blog posts on how they kill energy performance when they penetrate air barriers and that recessed fixtures are no longer necessary to achieve the same look. It’s true, you only need a standard Junction box but if you insist, or if you have to retrofit existing fixtures, here are some dry walled boxes that were done nicely.

This pot light in an attic floor was boxed with drywall then spray foamed with two pound foam. Nice work – but a lot of work.

This pot light in a floor cavity was lined with fire rated drywall and seams were sealed with fire-rated caulking. Nice work – but expensive labour-wise.

When spray foam fails, it can fail spectacularly, so when selecting an insulation system for your new or renovated building here are a few points to ponder when wanting to minimise environmental impact while maximising energy performance and durability of the building.

With spray foam gaining popularity in Ontario in the last 10 years, it’s especially important to shed light on new technology and stated claims. The progressive builders and architects we work with want to ensure spray foam was installed properly and we often get called to test newly installed spray foam before the drywall goes on. Using methods described in ASTM E1186, we test the foam with Infrared and the blower door. On every job, we find significant air leaks unless the foam wasn’t part of the air barrier system.

This high-rise going up now on the south side of College Street, just west of Spadina Ave had it’s walls spray foamed. Gauging from the colour chart below, Demilec’s HEATLOK SOYA was used. It would have been inconceivable 10 years ago, but the popularity of spray foam grows in Canada.

So testing aside, once you decide on the application requirements for either half or two pound foam, the important issues to focus on when considering spray foam include – who will install it, what is the global warming potential and can the foam be made from more benign feed stocks of oil.

First and foremost, it’s critical to mention that spray foam is not the “silver bullet” often purported by the spray foam industry: yes, the installed product has amazing properties, but it’s only as good as the installer who’s responsible for manufacturing the foam on site. The expectations for this process are established in the CAN/ULC-S705 standards.

Unlike panels of extruded or expanded polystyrene that you can buy at the building supply store which are manufactured in a carefully controlled manufacturing facility, spray foam is not. Spray foam is manufactured in situ on the job site. For this reason you want the person pulling the trigger on the foam gun to know how to make good foam, when/where to install it and who will back all this up with documentation about the lot numbers of each barrel of foam used including test results for the foam density and adhesion to substrate. Get a referral for the individual pulling the trigger, not the brand of foam, not the company. They guy pulling the trigger is key.

The manufacturing of spray foam in situ takes an experienced hand; hire the person pulling the trigger. The ‘A’ side of the equation is a commoditised product and is generic to both low and medium density spray foams. The ‘B’ side is proprietary and many companies (see colour chart below) make their own formulations, but the bottom line is that the chemistry is very similar. Just like bread, it can look, smell and test different, but the basics ingredients are the same; flour, yeast, salt, water and heat.

Spray foam needs a “blowing agent” in order to make uniform foam that’s stable, with many, small, gas-filled closed-cells. Currently, the bowing agents used in almost all medium density – AKA “Two-pound” – foams are of a high Global Warming Potential (GWP) which as the foam ages, is released into the environment. So it’s exciting news that Honeywell introduced a new blowing agent called Solstice with a GWP of 1. The story gets better because Elastochem, based out of Brantford Ontario, is manufacturing their proprietary ‘B’ component called Insulathane Extreme and any spray foam company in Ontario can purchase and install this spray foam. The same equipment is used for all foams and there’s no reason for any contractor to not switch to this Canadian made product today.

The last point we want to consider when choosing insulation is “what’s the embodied energy” of the insulation. In other words, what’s the “heat, beat and treat” process for the harvesting of and transformation of raw ingredients? Because the ‘A’ component is the same for all spray foams, only the ‘B’ formulation can be tweaked.

A few spray foam manufacturers boast of using plant-based oils in thier ‘B’ side proprietary formulation sourced from soya or castor beans. The good news is that it keeps a few farmer’s employed, but the sad reality is that these plant-based oils often may account for only 10% to 20% of the total volume and because the industrial farming practices of growing plants use oil-based fertilizers, herbicides and pesticides the benefits are marginal at best.

The flowing links will lead you to two great documents that can help you prepare your job site for spray foam and better understand what the spray foamer needs to be thinking about.

Bottom line, when selecting spray foam, know the person who’ll be pulling the trigger on your job site, try to select a spray foam that has a low GWP and test your foam for air leakage before you pay the foam contractor – they often have to come back to fill low spots, missed spots and some rare cases repair off ratio foam. Spray foam can be great, but it can be very unforgiving if installed incorrectly.

Imagine an ICF wall that snapped 4’x9’ sheets together like Lego, had 75% less concrete than conventional ICF which was replaced with high R-value foam and all structural steel was incorporated into the 50LBS panel. This isn’t a dream, it’s a reality and Pro ICF’s Chris Johnson has been building with this American technology called Hercuwall.

You don’t have to be Hercules to move these 5′x9′ 50 LBS panels! Install the metal tracks on the floor and slot the panel into the race.

The website describes the system as follows. “HercuWall® panels contain voids that are filled with concrete. These voids determine the shape of the concrete within the HercuWall® system which is analogous to a concrete stud wall. There are vertical concrete studs placed on regular 12” centers, a continuous concrete base, and a continuous concrete bond beam at the top of the wall. Each concrete stud attaches to a ShearStrip™ which are juxtaposed facing to the interior at one stud and the adjacent studs facing the exterior.”

Looking down into the wall of a window sill, you can see the voids for concrete as well as the and galvanized steel “Shear Strip” system that will be embedded into the Agilia.

Because there’s so significantly less concrete, there’s more room for higher R-value Expanded Polystyrene. With a lower GWP than XPS, the EPS panels come custom cut with rough openings that are actually not rough at all, but quite smooth and square.

The “rough openings” in Hercuwall are anything but rough. The CNC cuts are tight and square which to keep the soupy Agilia in, the bucks are made of what appears to be PVC.

Though BlueGreen Group hasn’t tested the builds for air tightness or thermal bridging yet, we’re anticipating that these walls will be more air tight than traditional ICF walls. In traditional ICF walls, we typically find a great deal of air leakage around rough openings as the concrete mixes used can be hard to work around the bucks. With Hurcuwall, the concrete used is LAFARGE’s Agilia and with a slump of 22” we’re expecting that voids around openings to be significantly minimized – all the same we look forward to testing a few of these buildings!