We like spray foam. Though I’ve been harping in recent posts like Pot lights and GBA that it needs to be air tightness tested with a blower door for air leaks – especially in Deep Energy Retrofits – the product is only as good as the installation. For a good installation you need an experienced qualified installer pulling the trigger.

What’s a Proper Installation Look like?

There are a couple of important distinctions to make when talking about spray foams. Firstly, spray foam is “manufactured in situ” by precisely mixing two thick liquids, an isocyanate with a polyol at a high pressure and temperature. In other words, the liquid in barrels schlepped by the foam guys’ truck isn’t called “foam” until it’s sprayed in place. The second point is that for residential use, the most common types of foam used are medium density, referring to foam with a rigid, closed cell structure and low density or open cell foam which has a cell structure that is open.

Not all sprayers are equal. In this photo, the HEATLOC SOYA was very evenly applied by an experienced sprayer. Note these stud cavities were in a bedroom with few obstacles that make foam a challenge; blocking, wires, plumbing etc.

Cell structure refers to the tiny bubbles that make up foam. Medium density spray foam has closed cells that trap gas in their cells. Closed cells have a higher R-value per inch and are more rigid that the open cell foams which are squishy and generally have half the R-value per inch than closed cell. Further, each spray foam brand has a slight variation in additives (usually colour) in one or both liquid components. Each brand (I.e.Icynene’s MD-C-200, BASF’s WalltiteECO or Demilec’s Heatlok SOYA) has to be tested by Canadian Construction Materials Centre to ensure the material meets CAN/ULC-S705.1-01.

The Ontario Building Code requires that manufactured medium density spray foam meets CAN/ULC-S705.1-01[i] which makes recommendations as to where the foam may be applied and how it’s to be tested and that the spray foam be installed according to manufacturer’s instructions and CAN/ULC-S705.2-05[ii]. CAN/ULC-S705.2-05 sets out the obligations of the manufacturer or supplier, the contractor and the installer. Don’t get me started on the fact that very few contractors have actually invested in buying the expensive sets of ULC standards and most installers have likely never read much less seen a copy of the standard.

There are a variety of tests that can be done on site and a good spray foam contractor will test their foam properties consistently. The physical properties of spray foam should be field tested at least once for every job site, every change in raw material LOT number and every day at the job site. Tests include:

- Adhesion to substrate

- Density

- Compressive strength

- Cell uniformity

The determining factors that go into a quality installation are twofold; the installer knowing enough building science to know where to spray the foam and finally to have a 3rd party firm air tightness test foam BEFORE the drywall goes on. Because medium density foam typically doesn’t fill the stud cavity completely, the air gap behind the drywall connects holes and voila, all you need is a bit of pressure on either side of the hole to drive conditioned air out. Just one hole in the spray foam can cause air leakage to negate the good intentions of the spray foam, but more typically, there are more than just a hole in the spray foam – did you see our pot light video- for retrofit foam jobs that don’t have an air barrier and depend on the spray foam to be the air barrier.

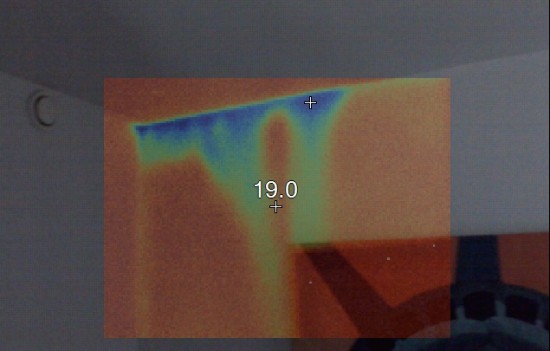

This infrared picture in visible picture of a bathroom wall detail shows air leakage behind the drywall. The blue denotes a plume of cool air washing the back of the drywall. Sadly, a blower door test could have probably identified the air leak which could have been repaired BEFORE the drywall went on.

[i] Standard for Thermal Insulation – Spray Applied Rigid Polyurethane Foam, Medium Density – Material – Specification.

[ii] Standard for Thermal Insulation – Spray Applied Rigid Polyurethane Foam, Medium Density – Application