If your build has the air barrier on the outside, you can ignore this blog post. The air leakage issues at the panel are only problematic when the 6mil. poly is the barrier and getting a good seal at all wire penetrations takes effort and attention to detail.

This pony panel will have fiberglass jammed around it and a poly taped to its metal carcass. Not a good air sealing strategy.

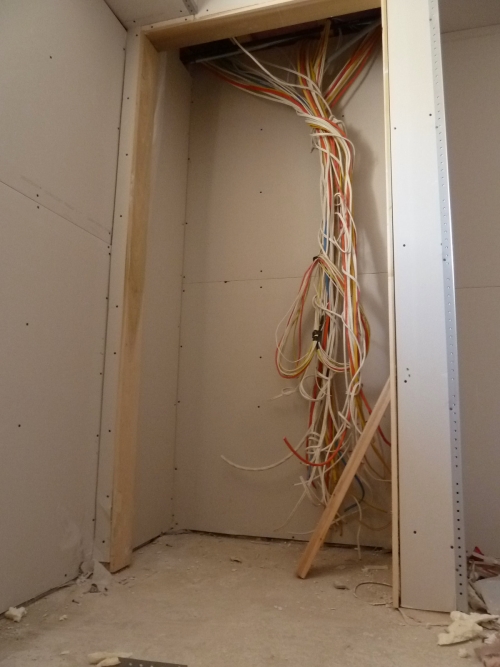

The poly was taped to the OSB and each wire penetration was caulked. The OBS to poly joint won’t be clamped and neither will the conduit to poly. This technique requires a great deal of effort and attention to detail and results in leaks air.

This method means the trades are without power in the house through most of the build, means the panel won’t be flush mounted and unfortunately, hides the wire penetrations in areas that are hard to seal.

The winner is… The poly covers the wall, 3/4″ plywood clamps the poly to stud faces and the main conduit is foamed in situ at rim joist. This strategy is robust and produces a fairly air tight panel area, but does require effort on the behalf of electricians and telecom wire installers.