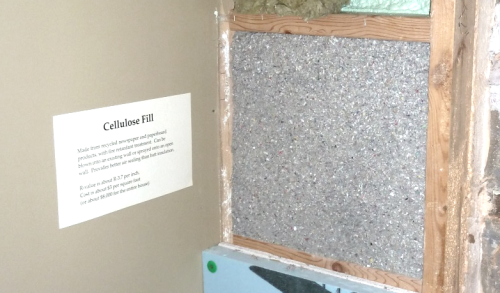

America, now more than ever, Canada needs your help. Yes, we need you to be firm on keeping XL out for the good of the world, but equally pressing we need your weatherisation training. The weatherisation industry in the USA has been on an upward trajectory for the last 20 years with support and contractor training readily available, but in Canada, we’re in the dark ages. Sure we have insulation contractors, but no weatherisation ‘industry’ or ‘sector’. Take the installation of dense pack cellulose for example.

We’re ‘hosers’, when it comes to ‘tubing’

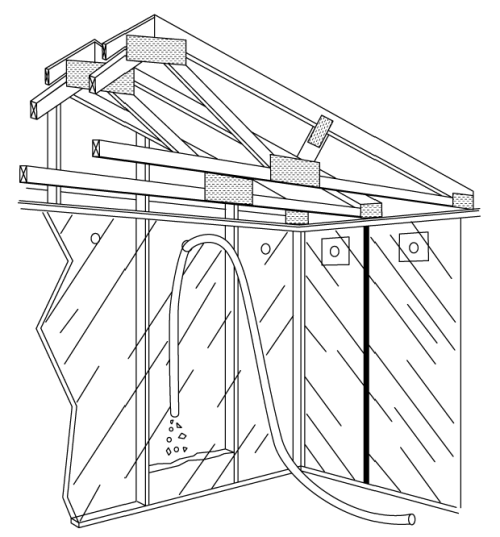

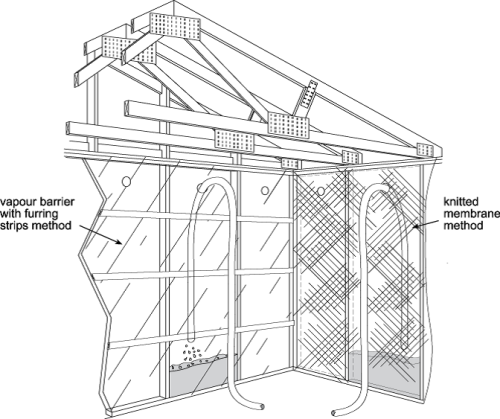

With a significant difference in energy savings, low cost to install, making homes quieter, an immediate all season comfort, with the least disruption and lowest impact on the environment to boot. It is a wonder that so few Canadian contractors install the product and when they do, do so poorly. In the US, cellulose is revered, but in Canada, never has such a great product been so mis-installed, especially in Ontario. In Canada we apply the same technique to dense packing walls as we do to fill our gas tanks; make a hole, stick the nozzle in and wait till it won’t take any more eh! See figures 1 and 2.

The theory of ‘Dense pack’ cellulose

Dense packing is not a DIY project; it is a physical job that takes experience, skill and care. There are two key aspects of successful dense pack cellulose; ‘tubing’ 100% of the walls and ‘high pressure’ on delivery. When cellulose is injected into the wall under pressure, it is compressed. The magic of cellulose lies in the fact that it behaves like a custom shaped sponge that’s slightly squeezed into a smaller cavity preventing it from ever settling and because it is so densely packed reduces convection and air leakage losses. Bill Hulstrunk of National Fiber does an awesome job explaining densities for thicker walls in new applications in this GBA video.

A short history of Canadian insulation grants

With every home energy conservation grant program introduced nationally, governments have failed to regulate the industry doing the building shell upgrades. In each of the 3 grant programs at no point were contractors certified, educated on ‘building as system’ or obliged to train staff on the proper retrofit techniques. Starting with the CHIP program where 2.5 million homes across the country got insulated between 1977 and 1986 followed by the EnerGuide for Houses performance program in the late 1990s to mid 2000s and most recently a prescriptive rebate program called ecoEnergy which ended a few years back. The salient points are that we lurch from program to program and a stable sector or industry has never emerged which surely contributed to the lack of interest on the part of contractors to learn building science principles nor were they regulated or certifications required. Unlike the USA, Canada has consistently eschewed the issue of contractor training and certification through organizations like BPI or RESNET.

The facts

There are a number of established facts on techniques for densepacking cellulose, but those facts don’t trickle up through the thick border between us. The stuff that Rick Karg and Jim Fitzgerald have been talking about for dozens of years like:

- Not all machines deliver the pressure needed for dense pack.

- Ensure by measurement you have a minimum air pressure – 2.9PSI- from your machine

- Probe all cavities

- Minimum density of 3.5 Lbs/ft3

- Tubing is an art, but there is science to it too, regardless training is key

- Test your work for density

Cellulose in New Buildings

Section 9.25.2.2 The Ontario Building Code (OBC) mentions in that the product of cellulose has to meet CAN/ULC-S703, but nothing else save a few words in the appendix. There is no directive in the OBC that describes a method for installing cellulose for new construction and if there is a reference in the OBC to Canada Construction Materials Centre’s (CCMC) documents or the manufacturer’s specifications, it isn’t obvious to find. CCMC produces Evaluation Reports and updates them every 3 or so years and these reports often reference the individual manufacturer for specifications on installation, but a quick scan through these hard to find documents and it’s obvious Canadian cellulose manufacturers have never attended an ACI talk on dense packing.

Cellulose Appelation d’Origine Controlée

For some reason, each manufacturer has a slightly different Evaluation Report and each manufacturer’s installation instructions differ in content. Either way, the referenced manufacturer instructions are not easy to find and when found lack detail on proper dense pack technique installation and completely ignore the retrofit market and at times seem to counter the CCMC document referencing it. The connection to the manufacturer becomes even more tenuous when retailers package cellulose as their own and don’t issue installation methods. Why the variation on technique? Are Canadian newspapers like French wines in that they vary significantly by region both in pithy quotes and white oak pulp content?

The Random Hammer Test

Ultimately, the manufacturer holds the bag on installation methods that support the CCMC, but few have made their standard readily available, and when they do, it’s the old “fill’er up” technique, no “stabbing” motion and with exceptionally few contractors in Ontario being aware this information is available. The CCMC document referenced in Appendix A below for IGLOO states whimsically:

The installation equipment consists of an adjustable blowing machine and a 62-mm diameter blowing hose with a minimum length of 30 m. By carefully controlling the filling time and filling pressure with the blowing equipment, the cavity will be filled completely to a minimum specified design density of 48 kg/m3 (3.0 Lbs/ft3).

Or if we go the Thermo-cell installer’s instructions they offer nuggets of wisdom like:

Density Verification – The …. target density of 48 kg/m3 or 40.5 kg/m3 (3.0 Lbs/ft3, 2.5 Lbs/ft3).

Quality Monitoring – Throughout the job the installer shall ensure through periodic bag counts that the correct amount of material is being installed.

Post Inspection – The installer shall be responsible for visually and physically inspecting the job to verify that all wall and ceiling cavities contain enough insulation and are firm to the touch. A random hammer test should also be performed.

These “instructions” are vague at best. Further, how is it that both Europeans[1] and Americans come up with the minimum density of 3Lbs/ft3 but prefer in the 3.5Lbs/ft3 and higher if stud cavity gets deeper than 4”? The CCMC documents have no minimum air pressure stated, no minimum machine requirements like an air lock, no specific instructions on how to achieve consistent density like a “stabbing” motion with a rigid hose and no in situ testing for density verification. The cellulose industry in Canada is the Wild West of insulation and no wonder the product gets a bad rap at times.

Figure 1: The “gas tank fill” technique. Evaluation Report CCMC 12420-R for Enviro-Sheild [2] which was re-evaluated 2009-11-09 and is subject to a re-evaluation 2012-12-08.

Figure 2: The “gas tank fill” technique, though evaluation Report CCMC 12835-R for IGLOO[3] is slightly newer (re-evaluated 2010-03-30 re-evaluation due 2013-08-21) with a slight modification to include strapping for poly, it’s still won’t guarantee density.

So what’s a Homeowner to do?

For new construction, the building code should make the reference to one accepted installation practice or CCMC needs to send the engineers who write their Evaluation Reports to RESNET or ACI for technical training. For retrofiting wall insulation we need to make sure weatherisation contractors know how to install the material. As Ontario and Toronto specifically look to start a 1000 home pilot program through financing with the Local Improvement Charge, it’s an opportune time to get it right like they’ve been doing south of the boarder for a generation.

The good news is, there’s a number of weatherisation contractors in the province who “Tube” walls and measure their machine output pressure. In the USA one contractor that shows proper technique on dense packing using rigid tubes is Larry Janesky, you can show this to your contractor or videos like this to help set the bar. If you want high performance insulation with a low embodied energy material in your next build or Deep Energy Retrofit but are unsure of your local contractor’s ability to deliver true “Dense-packed” cellulose, call us we can help train the contractor or do QA on the completed work.

[1] Insulation Materials, Testing, and Applications, Volume 4, By André O. Desjarlais, Robert R. Zarr, Symposium on Insulation Materials, Testing and Applications. 4, 2002, Charleston, SC., ASTM Committee C-16 on Thermal Insulation, American Society for Testing and Materials. Committee on Thermal Insulation.